Missouri S&T News and Events

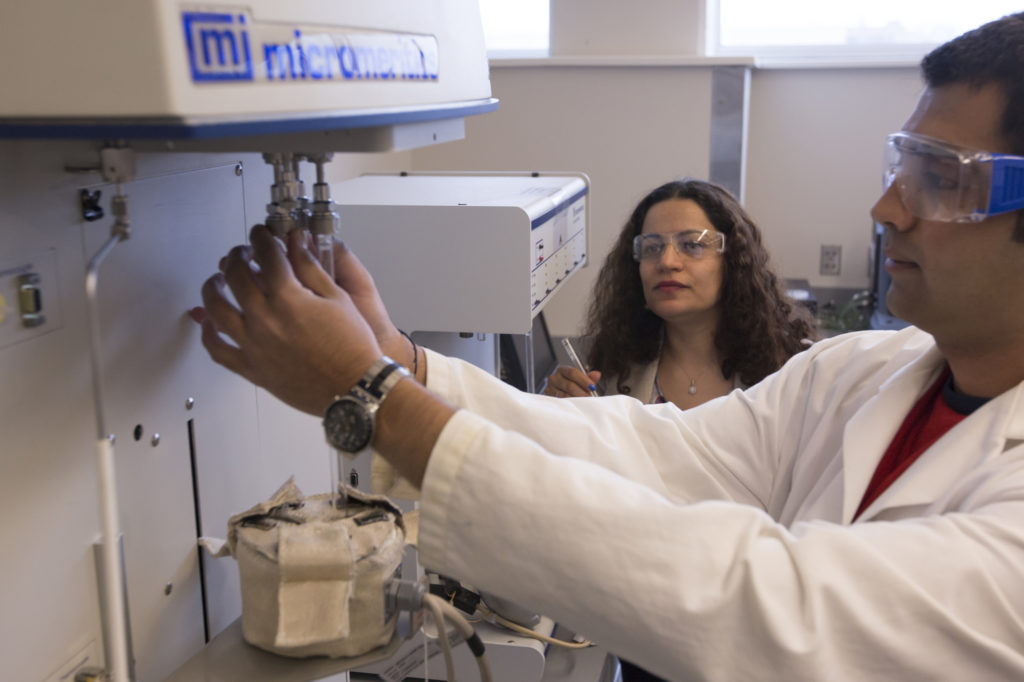

Missouri S&T professor Fateme Rezaei, left, and student Harshul Thakkar demonstrate their work to develop technology to help keep astronauts safe from carbon dioxide buildup.Sam O’Keefe/Missouri S&TA Missouri University of Science and Technology researcher and her team are developing technology that could help keep astronauts safe from carbon dioxide buildup during flight and aboard the International Space Station.

Dr. Fateme Rezaei, assistant professor of chemical and biochemical engineering at Missouri S&T, and the team have developed “robust structures” in mechanically strong configurations that are comparable to powders in adsorbing CO2. Their findings were reported in the American Chemical Society’s Applied Materials & Interfaces publications in September 2016 and February 2017.

Besides keeping astronauts safe, the technology can improve the reliability and efficiency of current CO2 removal systems. The work also could lead to the development of cost-effective and energy-efficient adsorbent systems for purification of other gas streams. Industrial gas separation processes include natural gas purification, olefin/paraffin separation and hydrogen gas separation.

In the study published in September, Rezaei’s team made 3-D printed 13X and 5A zeolite monoliths with novel structures — honeycombs in crosshatch patterns — to capture CO2 from the air. (“13X” and “5A” are commercial names of two types of zeolite materials.)

Results indicated that 3-D printed monoliths with high zeolite loadings show adsorption capabilities comparable to that of powder sorbents, she says. The adsorption capacities of 5A and 13X monoliths were 1.59 and 1.60 millimol per gram, respectively, using 5,000 ppm (0.5 percent) CO2 in nitrogen at room temperature.

The experiments show relatively fast dynamics for monolithic structures, Rezaei says. The printed zeolite monoliths show good mechanical stability that eventually can prevent attrition and dusting issues that are encountered in traditional pellets and beads packing systems.

“The 3-D printing technique offers an alternative, cost-effective and facile approach to fabricate structured adsorbents with tunable structural, chemical and mechanical ...

Read More

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.